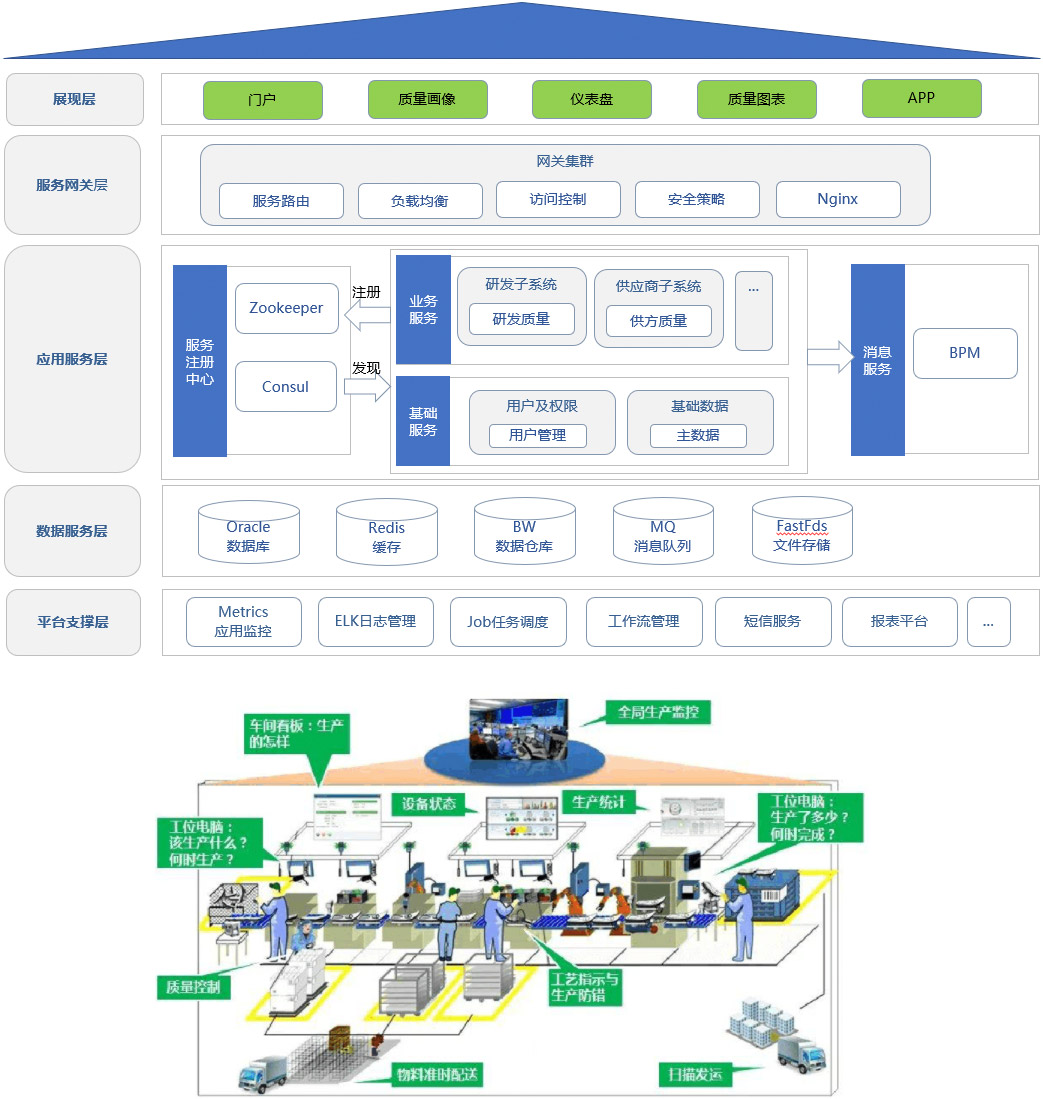

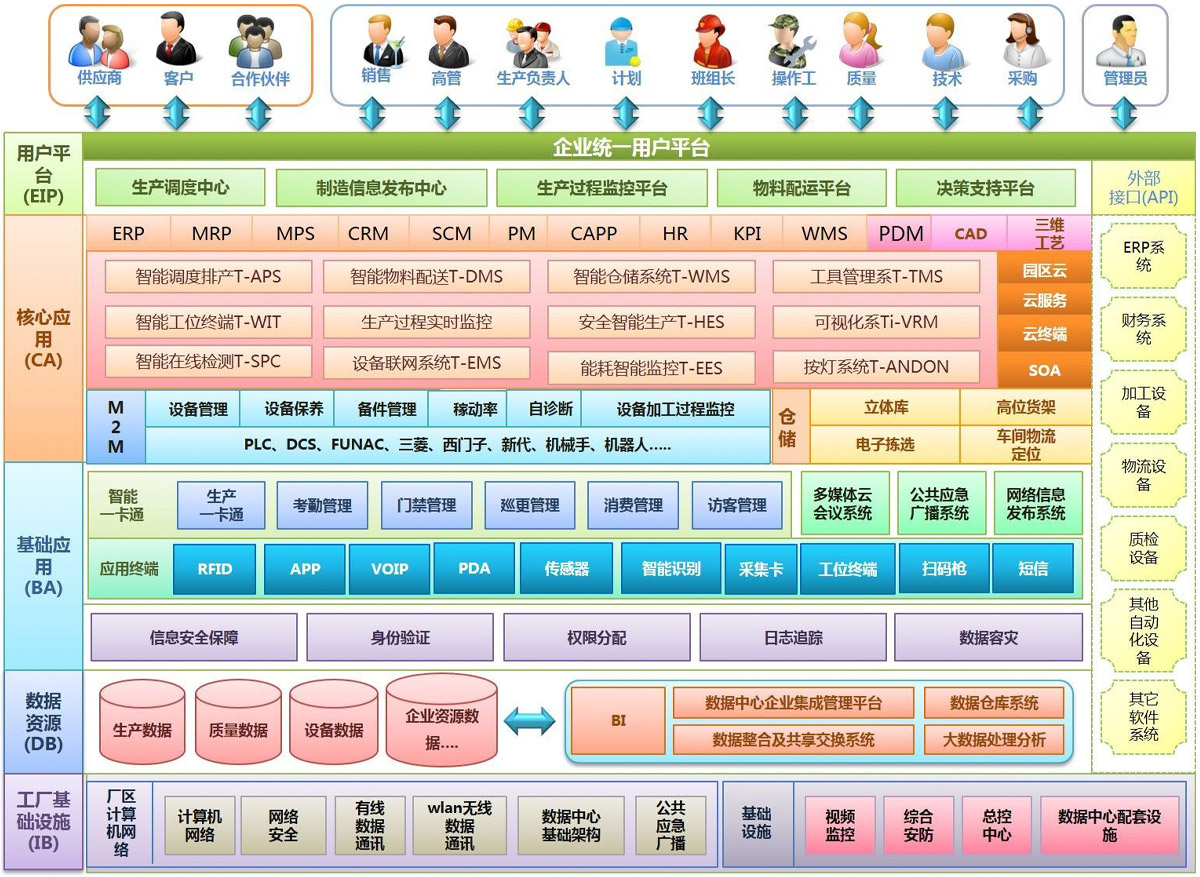

Eliminate isolated islands of

information; realize transparency

and visualization of factory

operations. production, and quality;

Eliminate isolated islands of

information; realize transparency

and visualization of factory

operations. production, and quality;

Realize the visualization and transparency of personnel management, and promote the improvement of QCD (quality, cost, delivery).

Realize the visualization and transparency of personnel management, and promote the improvement of QCD (quality, cost, delivery).

Realize the visualization of

materials and material flow status;

Realize the visualization of

materials and material flow status;

Realize the visualization of

inventory status;

Realize the visualization of

inventory status;

Realize the visualization of

optimized delivery of process work

orders;

Realize the visualization of

optimized delivery of process work

orders;

Visualization of business process

and business results (capital,

inventory, effective output, on-

delivery rate, etc.);

Visualization of business process

and business results (capital,

inventory, effective output, on-

delivery rate, etc.);