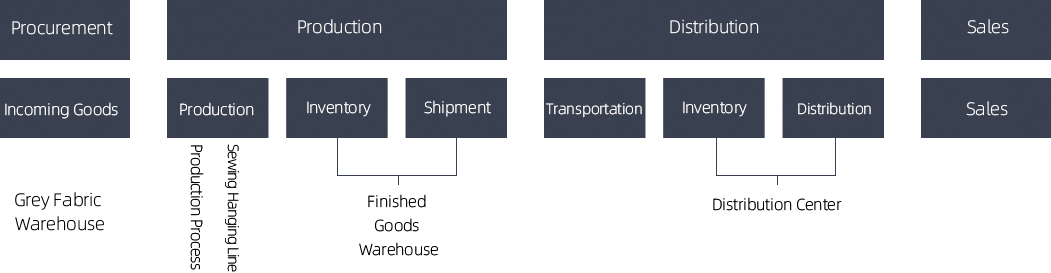

Cutting warehouse, auxiliary materials and production link cache

The workshop cutting warehouse, auxiliary materials and production link buffer processing center are located in the middle of the automated production line, used to store accessories, buffer

upstream semi-finished products, and pick and ship according to downstream production orders. The reserves are relatively small, but the variety of goods is complex and the efficiency

requirements are high

-

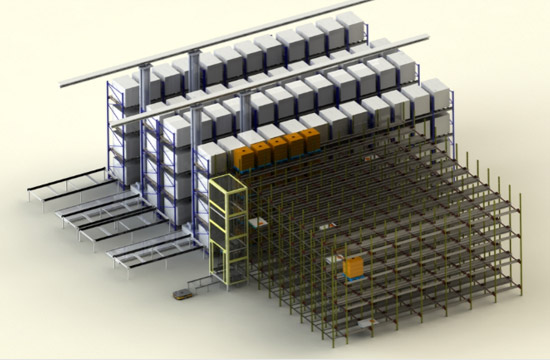

Material box AGV

-

I-BOX